A 3D print RC Car

I designed this fun little RC vehicle to be really easy to 3D print, with no supports and to be quick to assemble. It's got working, adjustable suspension provided by some elastic bands and uses a 9g servo for steering and two TT type gearbox motors to give it four wheel drive. It's not the fastest RC car you could make but it performs pretty well climbing up and over things, just like an RC crawler. We think making things like this that are easy to build, and fun to play with are a great way to get kids into 3D printing and STEM more widely.

Radio Control, Arduino, Raspberry Pi or Smartibot

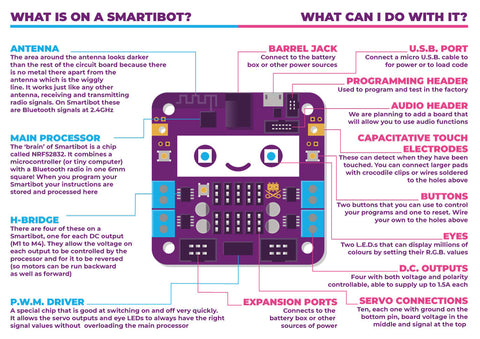

My truck uses the circuit board, gearbox motors and battery box from a Smartibot kit and is controlled using the Smartibot app, but you could make one using a standard radio control receiver and ESC (and control with a standard RC transmitter), or use an Arduino or Raspberry Pi and make your own controller. There's plenty of room under the bonnet for your hardware, and if you run out there is also the truck bed!

Balls, Vegetables or LEGO wheels

As well as being able to adjust the suspension you can also try out different wheels and tyres on your truck. I designed some proper monster truck looking ones to 3D print in PLA but also did a set of wheels you can print that you can fit squishy tyres made from tennis balls to, or you can print some adaptors so you can mount LEGO wheels, or another adaptor that lets you mount wheels made from vegetables. Our truck looked great rolling on turnip wheels.

Vitamins for 3D printers

Over here at Crafty HQ I run a Creality Ender 3 3D printer, which is remarkably effective considering its low price, but struggles with flexible materials. Also, as I don't have extraction set up and I don’t want to poison myself or my family, I print exclusively in PLA and PLA+. This means that I’m stuck printing with a fairly brittle material which makes things like tyres and suspension difficult. I’d designed and made a few vehicles with PLA wheels and no suspension and found that they tended to shake themselves apart because of all the vibration from everything being so stiff.

When we were designing the Smartibot I was keen to make sure that the parts could be re-used to make it much easier to make cool functional 3D prints like working robots and RC vehicles. I saw this tweet by Naomi Wu explaining how she uses the word ‘vitamins’ to describe parts that you don’t 3D print because they are “mass produced and easy to obtain” and adaptable enough that you can build lots of different 3D printed things with the same ‘vitamins’:

In digital fabrication vitamins are the parts in a design you do not fabricate yourself because they are mass produced and easy to obtain- like screws. Vitamins are sufficiently standardized you can build a huge variety of useful tools with a 3D printer and small box of vitamins.

— Naomi Wu 机械妖姬 (@RealSexyCyborg) January 29, 2020

I realised that we’d designed Smartibot to be a vitamin in this context and, because it can drive so many motors (14) and such a variety (4 high current DC motors that can run in either direction plus 10 servo motors or RC ESCs) and can be so easily adapted by creating a custom control pad in the app, I think it makes quite a useful one.

I started thinking more widely about other vitamins that are standardised and everyone can easily get and can solve mechanical problems that are difficult to solve with 3D printed PLA. With this truck those problems are mainly around getting compliance in the suspension and tyres. I saw that the LEGO Monster Truck (60180) uses elastic bands to work the suspension and I wondered if I could make that work and have steering at the same time. It ended up working much better than I had expected and the truck handles really well over rough terrain.

With vitamins in place for the suspension I still had an issue with the tyres. Then I remembered the WimbleBot, which had wheels made from a tennis ball and worked well on different surfaces. I though we would probably get the best performance out of the tennis ball if we could get it to seat on the wheel just like a real rubber tyre, so I 3D printed a little template which I used to mark two circles to cut out of the tennis ball. Again, despite the rough hand cutting, the tennis seated really well (and neatly) on the wheel, looks great and works well as a tyre.

Make Your Own Monster Truck

The files to 3D print all of the bits for this monster truck are over on Thingiverse:

https://www.thingiverse.com/thing:4404028

Assembly instructions are all in the video at the top of the page. If you make one it would be lovely to see it so please share a video or photo on Instagram, Twitter, Facebook, in the Reddit Sub, or just email it to hello [at] thecraftyrobot [dot] net. Also, let me know what you'd like to 3D print next and I get designing it!